Airtech Advanced Materials Group confirms expansion of LARGE SCALE ADDITIVE MANUFACTURING activity, with new European operation in Luxembourg

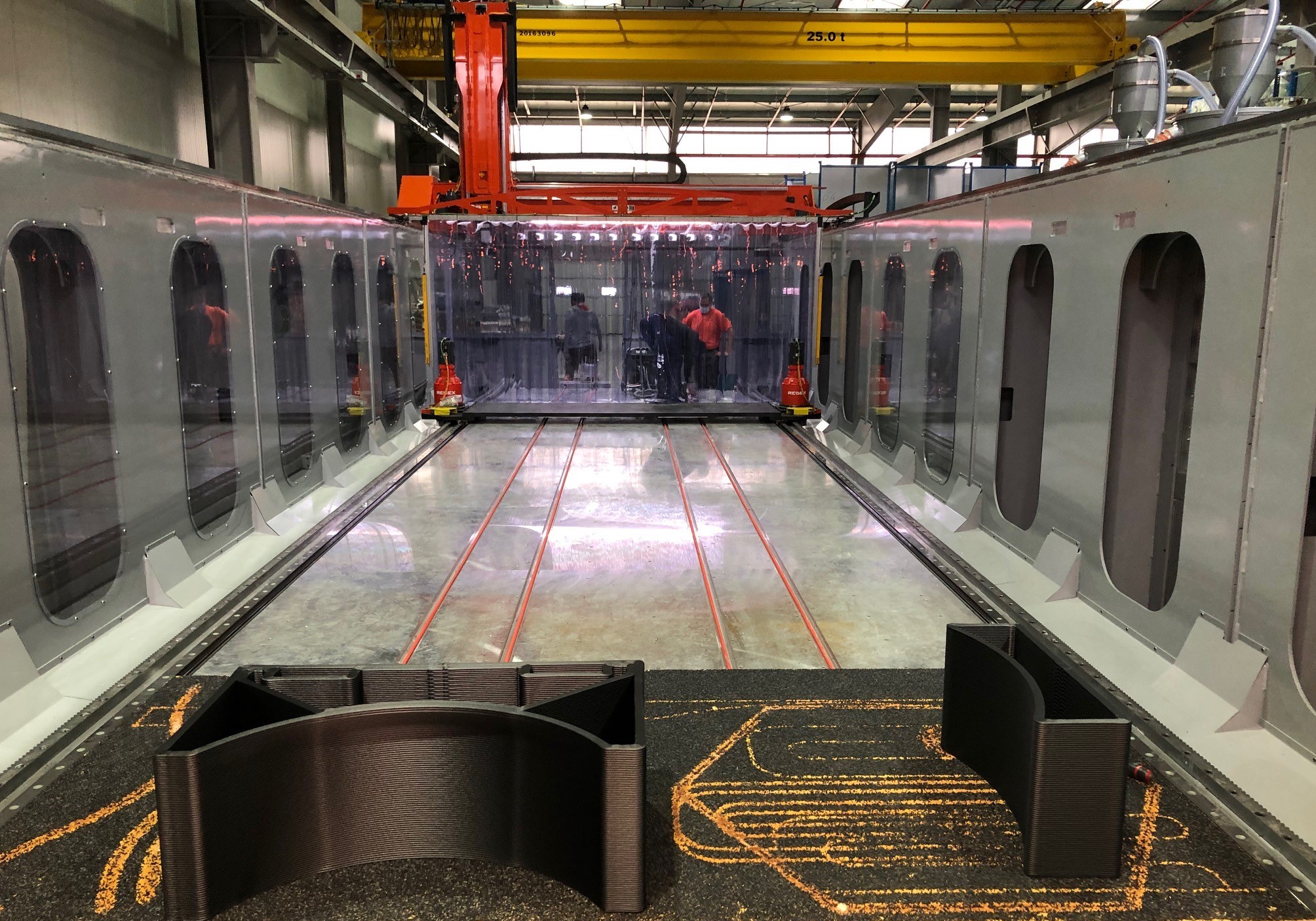

November 16, 2020Airtech Advanced Materials Group announced during Formnext Connect 2020, the installation of its second state-of-the-art machinery for Large Scale 3D Printing technology, operable now in its Airtech Europe facility, Luxembourg.

This is the second “Center of Innovation” to develop Tooling of Tomorrow (ToT), the first being opened by Airtech in Tennessee in 2019 and has the same capabilities to accommodate one of the largest machinery on the market, 12m x 3m (40’x10’) with integrated machining capability.

With Print-Tech® full-service tool manufacturing solution, Airtech can take tooling from conception to the shop floor significantly faster than any conventional methods. Print-Tech® Additive manufacturing deposits only the material required, resulting in less touch labor and shorter lead times. Large-scale tooling in the form of trim fixtures, holding fixtures, and layup molds can be designed, tooled, and built faster without compromising on quality.

Large Scale Additive Manufacturing is all about machinery, materials, and lot of expertise. With almost 50 years of thermoplastic extrusion expertise along with the most talented and knowledgeable staff in the industry, Airtech has developed a new series of innovative polymer composite resins. Dahltram® resins are for use in large scale 3D printing that has addressed the need for lower CTE and a more robust service life when used at low or high temperatures, including use in an autoclave. These thermoplastic composite resins are designed for use in any pellet fed FDM printing system. With both room temperature and high temperature material offerings, Airtech sits poised to meet the demands of its growing markets, ready to serve its customers.

“We are excited to announce the second “Center of Innovation”, being now able to offer numerous additive manufacturing services and solutions, helping our European customers to reduce cost and increase productivity,” said Jeff Dahlgren, President/CEO of Airtech Advanced Materials Group.

For more info, please visit our website: www.airtech3D.com